×

×

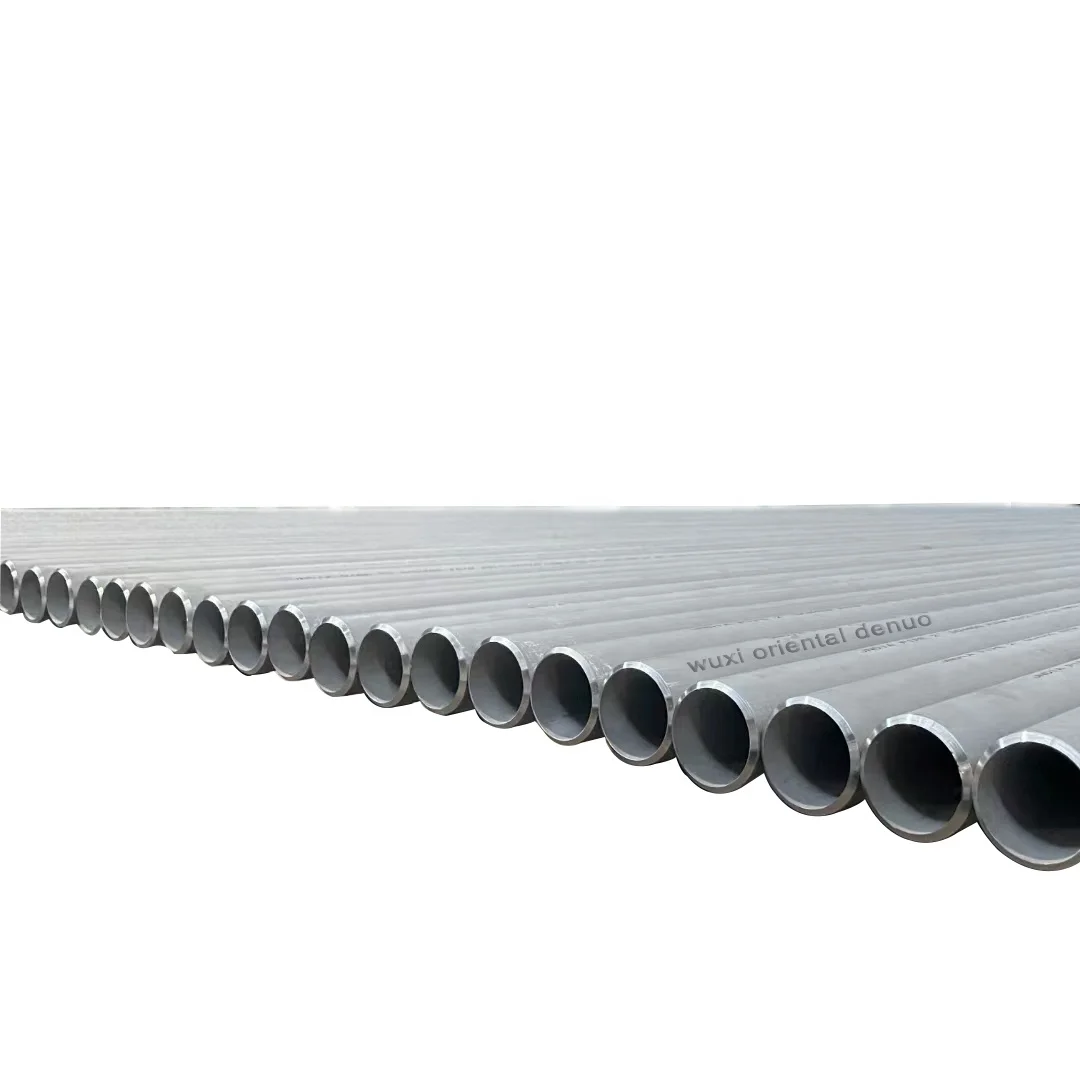

أنابيب السبائك التيتانيومية هي أنابيب قوية مصنوعة من معدن التيتانيوم، ولها خصائص ومزايا رائعة تجعلها شائعة الاستخدام في مختلف الصناعات.

أفضل جودة في أنابيب السبائك التيتانيوم هي أنها قوية جدًا. هذه القنوات مناسبة جدًا للاحتياجات عالية الضغط، مع مقاومة أفضل للكسر. هذا يجعلها خيارًا رائعًا لاستخدامها في نقل المواد مثل النفط، الغاز والسوائل المختلفة. بالإضافة إلى ذلك، فإن أنابيب سبائك التيتانيوم مقاومة للتآكل بحيث لا تتأكسد مثل أنواع أخرى من الأنابيب المعدنية. هذه المقاومة للتآكل تجعلها الخيار المثالي للاستخدام في المناطق التي تتعرض للرطوبة أو أي شكل آخر من أشكال الرطوبة.

لا حدود لاستخدام أنابيب سبائك التيتانيوم، ويمكن استخدامها على نطاق واسع في几乎所有 المجالات. يمكن العثور عليها في بناء الطائرات، السيارات وحتى المركبات الفضائية؛ وكذلك كعنصر أساسي في إنتاج المعدات الطبية مثل المفاصل الاصطناعية وصمامات القلب. يمكن أيضًا استخدام أنابيب سبائك التيتانيوم في مجال الموسيقى لحرفيين يصنعون أوتار الجيتار من هذا المادة الصلبة ذات الصوت الحيوي.

إن القوة المقاومة للشد وطبيعة أنابيب السبائك التيتانيوم الخالية من الصدأ جعلتها حلاً مرغوبًا فيه بشدة في العديد من الصناعات. تُستخدم هذه الأنبوب بشكل كبير في قطاع النفط والغاز لنقل الموارد الأساسية، وكذلك في القطاعات الصناعية القيمة مثل صناعة الطيران لصنع الطائرات/المركبات الفضائية. كما أن هذه الأنابيب مهمة أيضًا في المجال الطبي لإنتاج المفاصل الاصطناعية والعديد من الأجهزة الأخرى.

يُعزى ذلك إلى هذه الخصائص أن أنابيب سبائك التيتانيوم يمكن أن تساعد في تحسين أداء وإنتاجية العديد من التطبيقات. تُستخدم هذه الأنابيب، على سبيل المثال في صناعة النفط والطاقة، بهذه الطريقة يمكن للموارد أن تتدفق بشكل أكثر سلاسة مما يوفر الوقت وكذلك التكاليف. على سبيل المثال، في قطاع الفضاء تُستخدم أنابيب سبائك التيتانيوم لتحقيق هدف تقليل وزن الطائرات والمركبات الفضائية، مما يؤدي إلى تحسين أداء الرحلة وتحسين الاستخدام. وأهم من ذلك، فإن إضافة أنابيب سبائك التيتانيوم في التطبيقات الطبية يقلل من الاحتكاك والارتداء على الأجهزة الطبية مما يوفر عمرًا أطول لهذه المعدات الحيوية.

لماذا يجب أن تختار أنابيب سبائك التيتانيوم لتطبيقات مختلفة وما هي الفوائد للبيئة

اختيار أنابيب السبائك التيتانيومية يتيح تحقيق فوائد بيئية (لأنها تدوم لفترة أطول ولا تحتاج إلى استبدال). يتم تمديد عمر الأنابيب وهي تتطلب استبدال أقل مقارنة بمواد الأنابيب الأخرى بسبب طبيعتها القوية. بالإضافة إلى ذلك، كونها خفيفة الوزن جعلت من الممكن استخدام سماكات أرق وحفظ الموارد.

بشكل عام، تُعتبر أنابيب السبائك التيتانيومية جزءًا لا يتجزأ من قائمة اختياراتنا الثابتة والشاملة للاستخدام في العديد من القطاعات مثل القوة، المقاومة الممتازة للتآكل والمرونة. سواء في النفط والغاز أو الطيران وحتى الطب، نرى استخدام أنابيب السبائك التيتانيومية بشكل بارز كلما ظهرت الحاجة إلى أنبوب.

يتم توفير تصنيع أنبوب سبيكة التيتانيوم، مثل خدمات المعادن التي تشمل ثني المعادن، معالجة الحرارة، معالجة الصلب، حلول اللحام ومعالجة الصفائح المعدنية. المواصفات الخاصة مثل الدرجات الخاصة، الدفعات الصغيرة، التوزيع السريع للغاية، التوزيع السريع. النوع الكامل، المنتجات الرئيسية، بالإضافة إلى توفير سبائك درجات حرارة أعلى وهي السبائك القائمة على النيكل، سبائك الكوبالت، سبائك التيتانيوم، سبائك الألمنيوم. وكذلك السبائك الأخرى. والمعالجة المرتبطة بذلك.

توفر مجموعة واسعة من الأنابيب سبيكة التيتانيوم، الصفائح الفولاذية، القضبان الفولاذية، الحزم، الأشعة إتش وأشياء أخرى كثيرة. يتم تصديق جميع المخزون وفقًا لمعايير ASTM JIS BS EM وغيرها. اختبارات صارمة، سيتم تقديم الشهادات.

عند الحاجة إلى خدمة أنابيب سبيكة التيتانيوم، تم تطوير حل شامل معالجة واحدة، مثل ملحقات الأنابيب (تي، المرفقات، وما إلى ذلك). إنتاج اللحام المعالج للأنابيب معالجة الفlanges-المعين (لوحة مركبة انفجار)، السبائك، الحفر CNC، وغيره الكثير.

شركة ووشي أورينتال دينيو للتجارة الدولية المحدودة هي شركة كبيرة مقرها في ووشي، الصين، تدمج التجارة في أنابيب سبيكة التيتانيوم. أنابيب الصلب، صفائح الصلب، لفائف الصلب، القضبان، أشعة H متاحة بكميات ضخمة. متاحة، والتي تتوافق مع ASTM، JIS، BS، EM والمعايير الدولية الأخرى. متخصصة في خدمات المعالجة المخصصة OEM، القطع باللهب، القطع بالليزر، والقطع بالماس. المصنع الرئيسي المواد الخام المعالجة الدقيقة، 20 عامًا من الخبرة في مجال صناعة الصلب.